The computing part of the national Lisa computing cluster consists of 18 Dell EMC chassis with so-called blade servers (in addition to this computing part, Lisa also has servers for data storage). This modular design makes it easy to replace a part. In this way, we limit the amount of electronic waste as much as possible and use the equipment as sparingly as possible.

During Lisa’s last upgrade, in May of this year, we took a good look at which hardware could be retained. Thanks to the modular system, we only had to replace the blades. For the chassis (with built-in network switches and power supply), only the agreement with the support supplier has been extended.

Energy saving and recycling

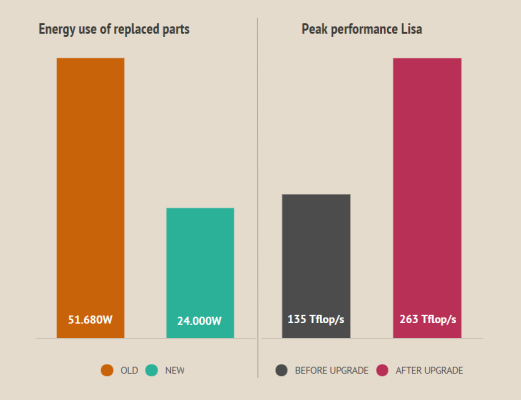

The new blades have 16 cores per CPU (central processing unit). Each blade uses 45 watts less power than the old blades. We disposed of 304 blades with CPUs of 170 watts, a total of 51,680 watts. This was replaced by 192 blades with a CPU of 125 watts; a total of 24,000 watts. This saves us 27,680 watts. For the disposal of the hardware, we work together with SIMS Recycling Solutions. SIMS resells the used equipment and receives a similar amount of e-waste from the buyer for responsible recycling. Thus the circle is complete.

Computing power almost doubled

The new blades are much more efficient: with fewer blades, Lisa’s computing power has almost doubled. The cores can process more tasks per clock cycle using avx512 instructions. With the new blades, Lisa’s peak performance increased from 135 Tflop/s to 263 Tflop/s (teraflop per second).

With a set of 96 blades that were not yet ready for replacement, we have optimized the utilization of the memory banks. By this redistribution of existing memory supplemented with new memory, even without replacing blades, a speed gain was achieved.

We have achieved further optimisation and efficiency in the use of the equipment by using a batch environment that determines the order in which the jobs are executed (bare-metal cloud). Until now, it was only possible to assign entire blades to users. Using scripts, it was then possible to run multiple programs simultaneously on one blade. The new blades have a fast SSD disk for local scratch storage. This makes it possible to run multiple batch jobs of different users on one blade at the same time.

Lisa: hundreds of computer tasks at once

The Lisa compute cluster is ideally suited for large-scale calculations. You can imagine a cluster computer as a collection of ordinary computers (also known as nodes) that are connected to each other via network cables. Each node has its own processor, memory and disk space. In addition, they generally have access to a shared file system. On a cluster computer, you can perform hundreds of computer tasks simultaneously. Researchers use Lisa, for example, for genetic research, machine learning or text analysis.

Accountability by our suppliers

We have asked our suppliers to assess the environmental impact of the products we buy as much as possible. Dell EMC reports that the PowerEdge M640 Servers are manufactured in Lodz, Poland. The parts are transported by train from China to the production facility. This method of transport is much less harmful to the environment than transport by boat or plane.

From Poland, the servers are transported by road to the central European distribution centre in the Netherlands. Trucks with Euro 6 engines (the ‘greenest’ European emission standard) are used for this transport. Thanks to planning systems, optimum use is made of the available loading space.

Dell EMC uses recycled plastic in the PowerEdge servers for components such as ventilation covers and frames. In total, 27.5% of the plastic used is recycled. More than half of the packaging used during transport is made from sustainable materials. For more information on Dell EMC’s efforts in the field of packaging, please visit the Dell.com website.

The servers arrived from the factory on 16 pallets at our supplier Bossers & Cnossen. With the removal of excess packaging material, this number has been reduced to four. These four pallets were transported by Euro 5 truck to SURF’s data centre. All packaging materials are processed by Bossers & Cnossen in an environmentally friendly way. Cardboard, polystyrene foam and plastic are processed separately and reused where possible. The packaging material used for the four pallets that went to the data centre was produced sustainably and is also reused if possible.

Want to know more?

Contact Leonieke Mevius, project manager sustainability at SURF: leonieke.mevius@surf.nl

0 Praat mee